PALL didirikan oleh Dr. David B Pall di New York, AS pada tahun 1946, berfokus pada penelitian dan produksi filter dan sistem pemisah filtrasi. Pall berkantor pusat di New York, Amerika Serikat, dengan anak perusahaan, pabrik manufaktur, dan riset dan lembaga pengembangan yang tersebar di lebih dari 40 r

PALL didirikan oleh Dr. David B Pall di New York, AS pada tahun 1946, berfokus pada penelitian dan produksi filter dan sistem pemisah filtrasi. Pall berkantor pusat di New York, Amerika Serikat, dengan anak perusahaan, pabrik manufaktur, dan riset dan lembaga pengembangan yang tersebar di lebih dari 40 wilayah.

Kombinasi tempat tidur filter pra lapisan penyaringan dari elemen filter sistem. Terdiri dari lapisan serat ultra-halus, lapisan pendukung, lapisan filter, dan lapisan penata gravitasi, semua partikel padat lebih besar dari 3AspirinM dalam keluaran udara dari kompresor dapat disaring, sementara partikel gas dan air minyak yang sangat kecil sekitar 0.01-1AspirinM kental ke dalam tetesan minyak yang lebih besar saat melewati elemen filter, yang terkumpul di bagian bawah elemen filter, dan kemudian menyedot kembali ke sistem pelumasan melalui pipa minyak kembali di bagian cekung dari elemen filter bawah, sehingga kompresor dapat melepaskan purer dan udara terkompresi bebas minyak.

Penggunaan kartrid Filter:

(1) elemen penyaring padl harus dipasang di port hisap pompa: filter oli tipe permukaan biasanya dipasang pada jalur hisap pompa untuk menyaring kotoran dan partikel yang lebih besar untuk melindungi pompa hidrolik. Selain itu, kapasitas penyaring filter oli harus lebih dari dua kali tingkat aliran pompa, dan kehilangan tekanan harus kurang dari 0.02 MPa.

(2) elemen penyaring padl dipasang pada sirkuit oli stopkontak dari pompa: Tujuan memasang filter oli di sini adalah untuk menyaring kadar keluar yang dapat memasukkan komponen katup dan bagian lain. Akurasi filtrasi harus 10-15AspirinM, dan harus dapat menahan tekanan kerja dan tekanan benturan pada sirkuit Oli, dengan tetesan tekanan kurang dari 0.35 MPa. Pada saat yang sama, katup keselamatan harus dipasang untuk mencegah penyumbatan filter oli.

(3) elemen penyaring empedu dipasang pada saluran oli pengembalian sistem: pemasangan ini berfungsi sebagai filter tidak langsung. Biasanya, katup tekanan belakang dipasang paralel dengan filter. Ketika filter menjadi macet dan mencapai nilai tekanan tertentu, katup tekanan belakang terbuka.

(4) elemen filter pall dipasang pada sistem cabang sirkuit Oli.

(5) PALL elemen filter sistem filtrasi terpisah: sistem hidrolik besar dapat dilengkapi dengan pompa hidrolik khusus dan filter minyak untuk membentuk sirkuit filtrasi independen.

Selain filter oli yang diperlukan untuk seluruh sistem, filter oli halus khusus sering dipasang di depan beberapa komponen penting (seperti katup servo, katup klep penutup presisi, dll.) untuk memastikan operasi normal mereka pada sistem hidrolik Pall filter.

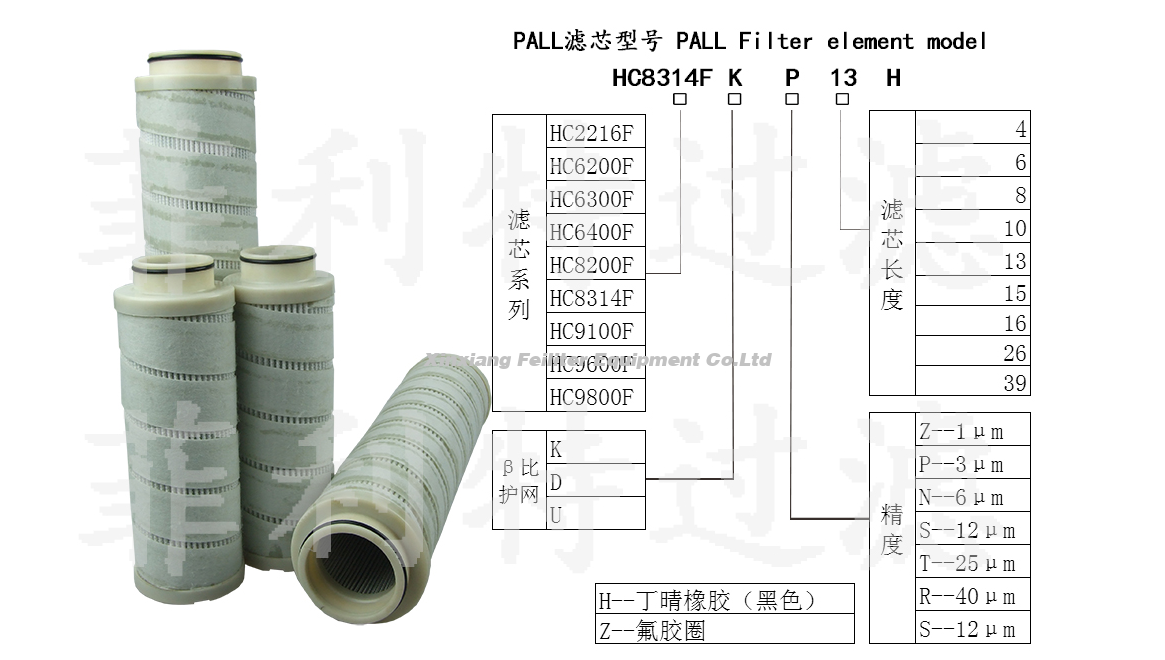

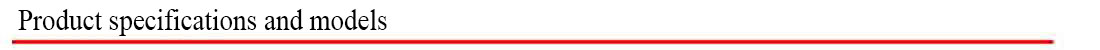

Catatan: HC7400S dan HC7500S adalah seri filter opsional, silakan hubungi kami untuk model lain

Untuk pertanyaan model seri PALL UE, silakan klik di sini

Tren produk, tips, dan berita langsung dikirim ke kotak masuk Anda